Epoxy Injection Grouting – A Constructive Crack Repair Method

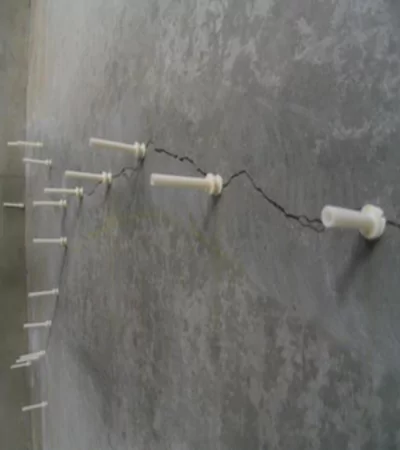

The Epoxy injection grouting method consists of a solvent-free base material called epoxy resin and a low viscosity liquid hardener.

The method of epoxy injection grouting may take place with free-flow under gravitational force or by injecting using a hand or mechanical pump.

This is by far the most effective method of repairing cracks in concrete structures. The process of epoxy grout is taken into consideration depending on the type of crack, its width and depth.

Epoxy Injection grouting helps to fill the joints, cracks, and spaces between old piping and new pipe.

The cracks in concrete is filled up by injecting a low viscosity epoxy resin into the cracks. The method of epoxy injection grouting ensures crack sealing and provides structural strength that is stronger than the original concrete. Epoxy grouting also helps in sealing the cracks thus avoiding the leakages rom the crevices in rcc / tunnel concrete lining.

Key Benefits of Epoxy Injection Grouting

- Epoxy injection grouting is preferred owing to its quick setting and very low viscosity shrinkage.

- The epoxy grout method acts as an excellent adhesive and has high strength.

- The low viscosity of the epoxy injection grouting protects the formation of hairline cracks and provides good resistance to most chemicals.

- Epoxy grout is a waterproof method and is also known to entirely stain-resistant.

- It helps in filling and bonding cracked concrete.

- Epoxy grout act as structural support in areas where a grouting solution is required and where dynamic load resistance is required.

The epoxy grout method requires deep-dive knowledge, research and development by expertise for application. Hence choosing the right company for epoxy injection grouting service is very important. If you are looking for an effective epoxy grout service, then Gubbi Civil Engineers is where you need to be. We are known to provide the best and successful epoxy injection grouting services under expert supervision.

Quick Enquiry Form!

Grouting Contractors

Get your brochures

Contact us

- Address: Gubbi Civil Engineers, 3rd Floor, Odessa Boutique Offices, Rd Number 9, Near Old Passport Office, Wagle Industrial Estate, Thane (West), Maharashtra - 400 604.

- Phone: 7498523824 / 9820636360